Voltaic designs and manufactures custom, high-quality solar power panels and mounting solutions for a wide range of industrial applications including transportation, agriculture, parking, and environmental monitoring. We work with you to understand your dimensional and power requirements, translate those into technical drawings, test for performance within your design, and manage the supply chain and import process.

Custom Solar Panel Design Process and Options

Our team typically follows a four-step development process:

1. Exploratory Discussion - A combination of phone and/or email conversations to understand your complete project requirements, quantities, and timeline.

2. Panel Specifications and Design - We produce one or more panel drawings that include dimensions, material, voltage, power, materials, wiring, and mounting mechanism.

3. Samples - If needed, we produce samples for testing within your design. There are a range of mechanisms to test for performance and durability against your specifications.

4. Full Production - Panels are produced at scale. We manage QA and the import process.

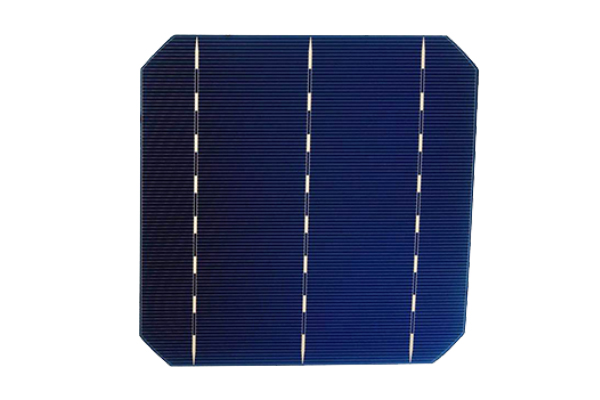

^back to topTotal power is determined by surface area and solar cell efficiency. We most frequently use both standard monocrystalline cells and SunPower back contact cells.

We cut laser cut those cells into smaller, equal-sized pieces and assemble them into a panel. The more cell area, the more power is produced.

| Example Cell | Cell Type | Dimensions (mm) | Total Power (Watts) | Power per cm^2 (Watts) |

|---|---|---|---|---|

| Motech 19.5% 3 Busbar Cell | Monocrystalline | 156 x 156 | 4.76 | 0.0195 |

| EEPV 21.2% 5 Busbar Cell | Monocrystalline | 156 x 156 | 5.18 | 0.0212 |

| SunPower 23.1% Maxeon Gen III | Mono Back Contact | 125 x 125 | 3.54 | 0.0231 |

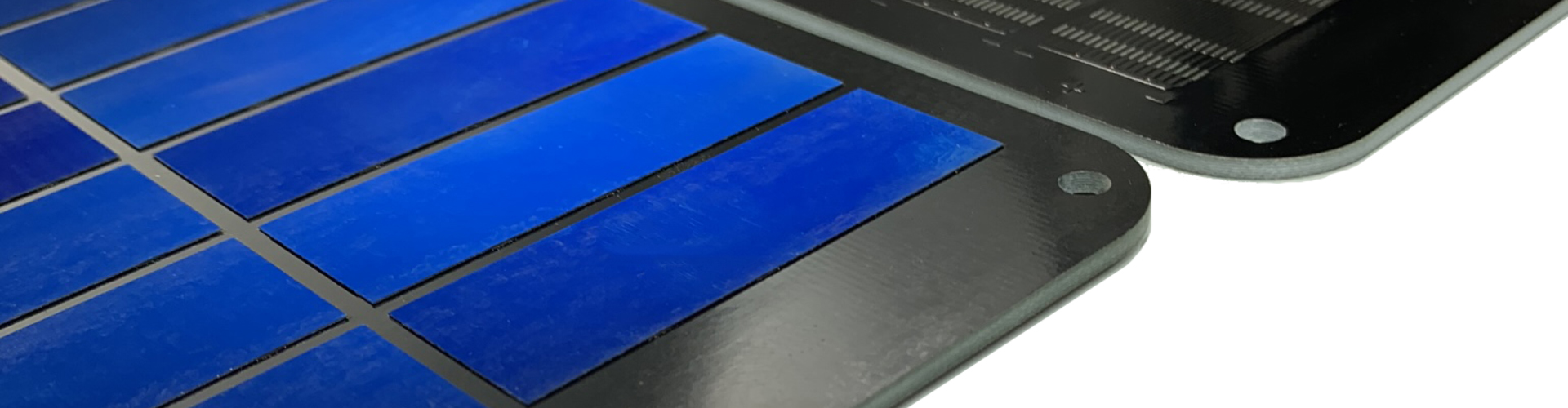

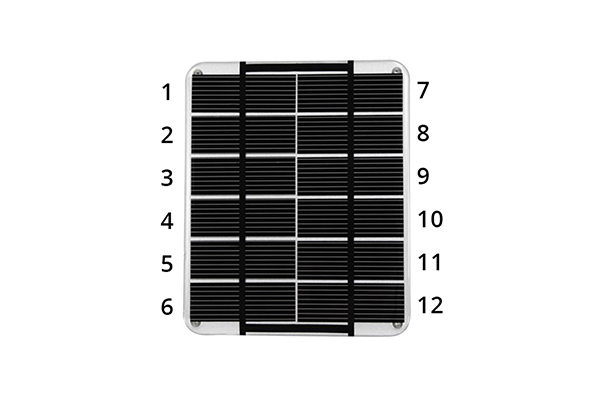

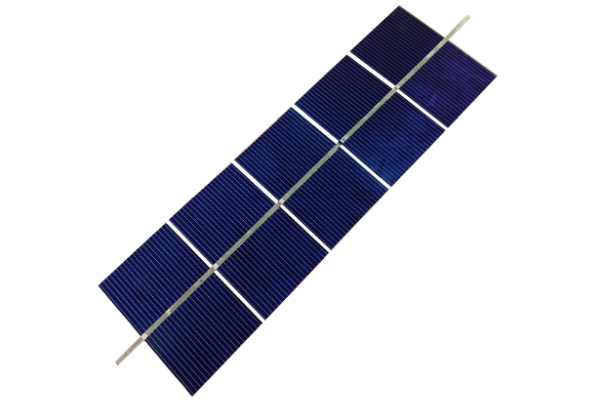

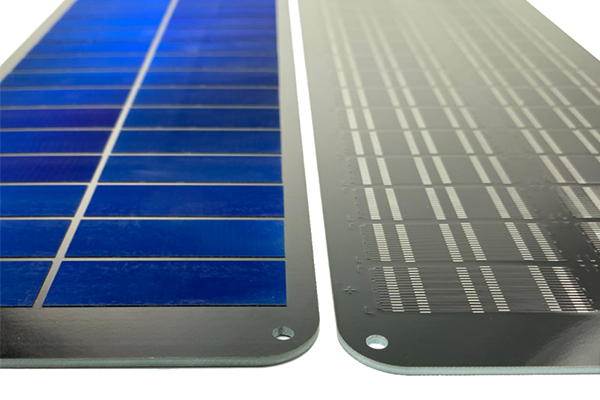

For example, this monocrystalline panel on the left has 118 cm^2 of cell area (12 52mm x 19mm pieces) using 19.1% efficient cells and is rated for 2.3 Watts. The SunPower panel on the right has 129 cm of cell area (18 50mm x 14.4mm pieces) using 23.1% efficient cells and is rated for 3.0 Watts.

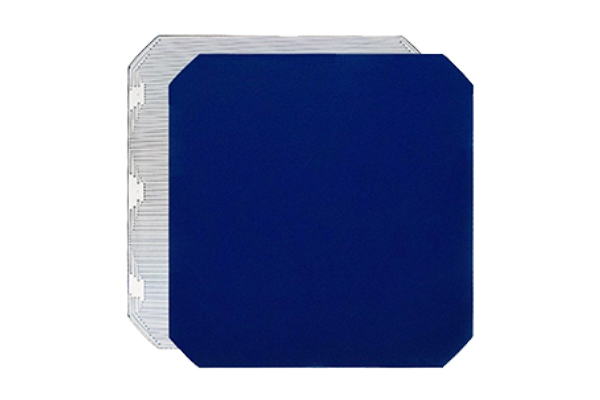

SunPower cells gain much of their efficiency by moving their tracer lines and connection points to the back of the cells. While more expensive on a per Watt basis, SunPower cells (vs. traditional monocrystalline cells) have:

- Higher efficiency - roughly 15% additional power per unit area

- Strong copper connections maintain power even if a cell is cracked

- Fewer constraints to cell size and layout when using an SMT production process

- Even appearance can disappear on a matte black background

- Slightly more physical flexibility

The downside of SunPower cells is that they cost more on a per Watt basis than traditional monocrystalline cells. On larger panels, there are also more constraints on how the cells can be cut. SunPower are available with ETFE or glass.

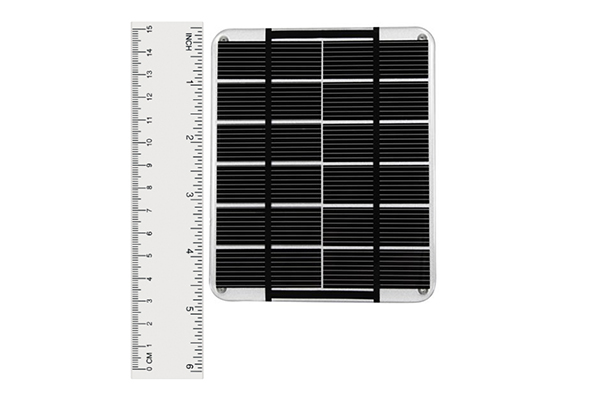

We create a specific voltage by stringing individual cell pieces in series. Each cell piece is ~0.55 Volts (0.58 - 0.59 for SunPower), so for the 2.2W panel shown below, we used 12 pieces to create a 6 Volt panel.

Where possible, we recommend producing as low a voltage panel that works for your circuit. Here are some of the advantages of a lower voltage panel:

- Higher current - In the same area, an 18V panel will produce less current than a 16V panel. Your circuit may waste that excess voltage leaving you with 12.5% less power.

- Higher power - Each cell requires a gap between the next cell. The more cells on a panel, the more area is wasted to the gaps between cells.

- More partial shading and fouling risk - If an object adheres to or partially shades the panel, the power loss will be greater on a higher voltage panel. A string of cells generates as much current as the worst performer in the string. When cell pieces are smaller, the shading impact increase.

- Slightly more expensive to manufacture - more pieces equates to more labor

^back to top

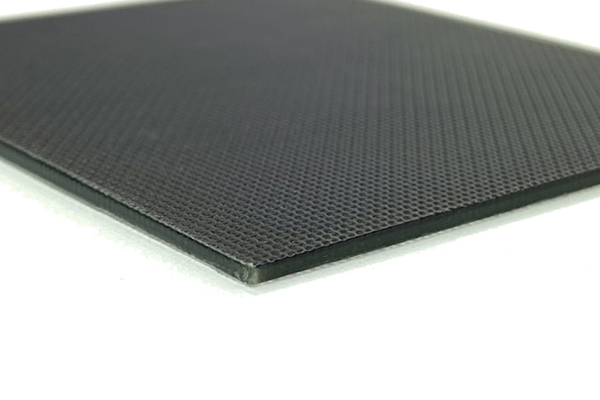

Urethane: Highly UV resistant and durable. Our urethane solar panels last up to 10 years in the sun with minimal power degradation. The urethane coating is poured or "potted" on the solar cells and leads to a highly waterproof panel. Each individual cell is completely encapsulated by the urethane.

ETFE: Economical, waterproof and UV resistant. Solar cells are attached to the substrate and then laminated under heat and pressure by EVA and ETFE. With high-quality materials (there is a difference in the production quality of ETFE and EVA), our ETFE solar panels have an expected life of 7+ years outside.

Epoxy or PET: Panels made with these coatings will be inexpensive, but we don't recommend this coating for most industrial applications as it tends to have a relatively short lifetime. They are the least UV resistant of any of the options.

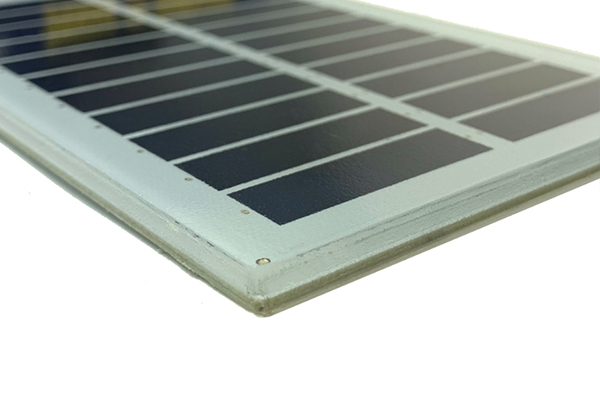

Glass: Great UV resistance and combined with a frame, a glass panel can have the longest lifetime. Glass panels are the heaviest on a per Watt basis.

From Left: Urethane, ETFE, PET, Glass

| Coating | Expected Lifetime Outdoors (Years)* | Typical Thickness (mm) | Approximate Weight of 5 Watt Panel (kg) | SMT Available |

|---|---|---|---|---|

| Urethane | 10+ | 5 | 0.25 | No |

| ETFE | 7+ | 2.5-3.5 | 0.21 | Yes |

| Glass | 10+ | 5 | 0.37 | Yes |

| Glass with Frame | 15+ | 20 | 0.49 | Yes |

| PET | 2-3 | 2.5-3.5 | 0.21 | Yes |

*Lifetime will vary based on a wide range of factors including panel design, materials used, production process, physical environment and other operating conditions.

^back to topThe solar cells are mounted on a substrate or backing. Again, there are several options.

Aluminum-Plastic-Aluminum: Very high strength to weight ratio material used in commercial building applications. Allows embedding of screw or nut into substrate. Only available with our urethane panels.

PCB Plastic: Different thicknesses available, from 0.6mm to 3mm depending on requirements. Higher density than Aluminum-Plastic-Aluminum substrate.

TPT: No rigidity but is paired with glass panels as the glass provides the structural support.

^back to topThere are two ways we connect the cell pieces in series.

The more traditional way is to solder the positive of one cell piece to the negative of the next cell piece with a ribbon. This can be done by hand or with what's called a stringing machine. One or more strings are then placed on the substrate and connected as needed.

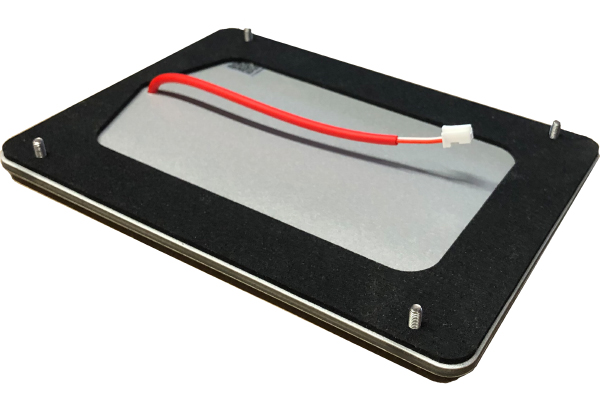

The SMT method starts with a PCB that matches the back contacts of SunPower cell pieces. Cell pieces are placed onto the PCB by a modified SMT machine normally used for pick and place of components. The PCB and cells are sent through a reflow oven to solidify the connection.

SMT provides more flexibility on cell layout and size and is our preference when making 1 Watt or less panels. At higher power, stringing cells is typically more economical.

^back to topIn addition to customizing the embedded screws or adding through holes, we offer the ability to create a custom panel mount for your specifications. This includes the design and manufacture of custom brackets, gaskets or VHB seals.

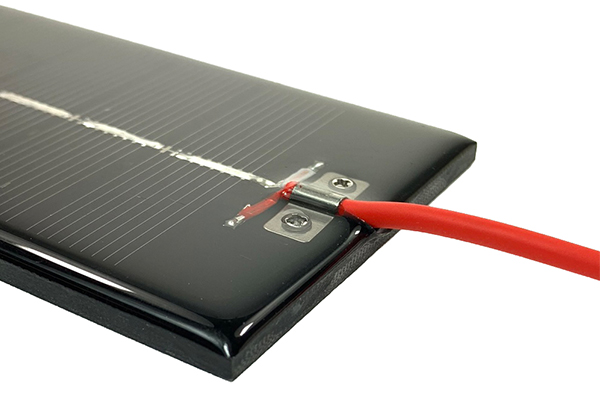

Our standard wire has strain relief is about 12 inches long and terminates in a 3.5x1.1mm plug. This can be changed to whatever length and terminal you prefer. The wire can be embedded into the substrate to keep it waterproof or soldered on the outside of the panel. Power and ground wires can even be separated. Another option is to place contact pads on the back of the panel. These can be positioned anywhere on the panel.

On the back of our ETFE panels, we normally cover the connection to the wire with silicone sealant and a junction box. This combination provides both waterproofing and strain relief. We have other junction boxes available for higher gauge wires.

There are no design fees to create a prototype of your custom solar panel. Some, but not most, designs may require a fee to prepare the machinery to create your specific panel at volume.

^back to topOur MOQ is 500 - 2,000 units depending on the size of the panel.

^back to topSolar panels brought into the United States are subject to a wide range of countervailing and anti-dumping duties. If not managed properly, duties on panels can exceed 200%. We manage that risk for our US customers, by importing and clearing panels prior to delivery.

We think about the panel import process from the very beginning of the design process by selecting solar cells and manufacturing locations to minimize those tariffs and keep costs down.

^back to top- Estimate your realistic solar power production in worst-case scenarios. Here's how to estimate solar irradiance by month based on your expected location(s).

- Reduce your circuit’s power requirements before discussing the panel’s power requirement. For example, if you can reduce your circuit’s mA requirements by 50% this reduces the size of the solar panel by 50%, saving you money, size, and weight.

- Prototype your project with small solar panels before moving forward with custom designs. This allows you to confirm the efficiency of the circuit and power production estimates before investing in a custom design.